In Praise of Tape Measures: the high value of low-tech tools

Part of the fun of being an architect is the wide variety of tools we use, from pencil sketches and cardboard models, to computer renderings that are so detailed they can be mistaken for a finished building.

Measuring

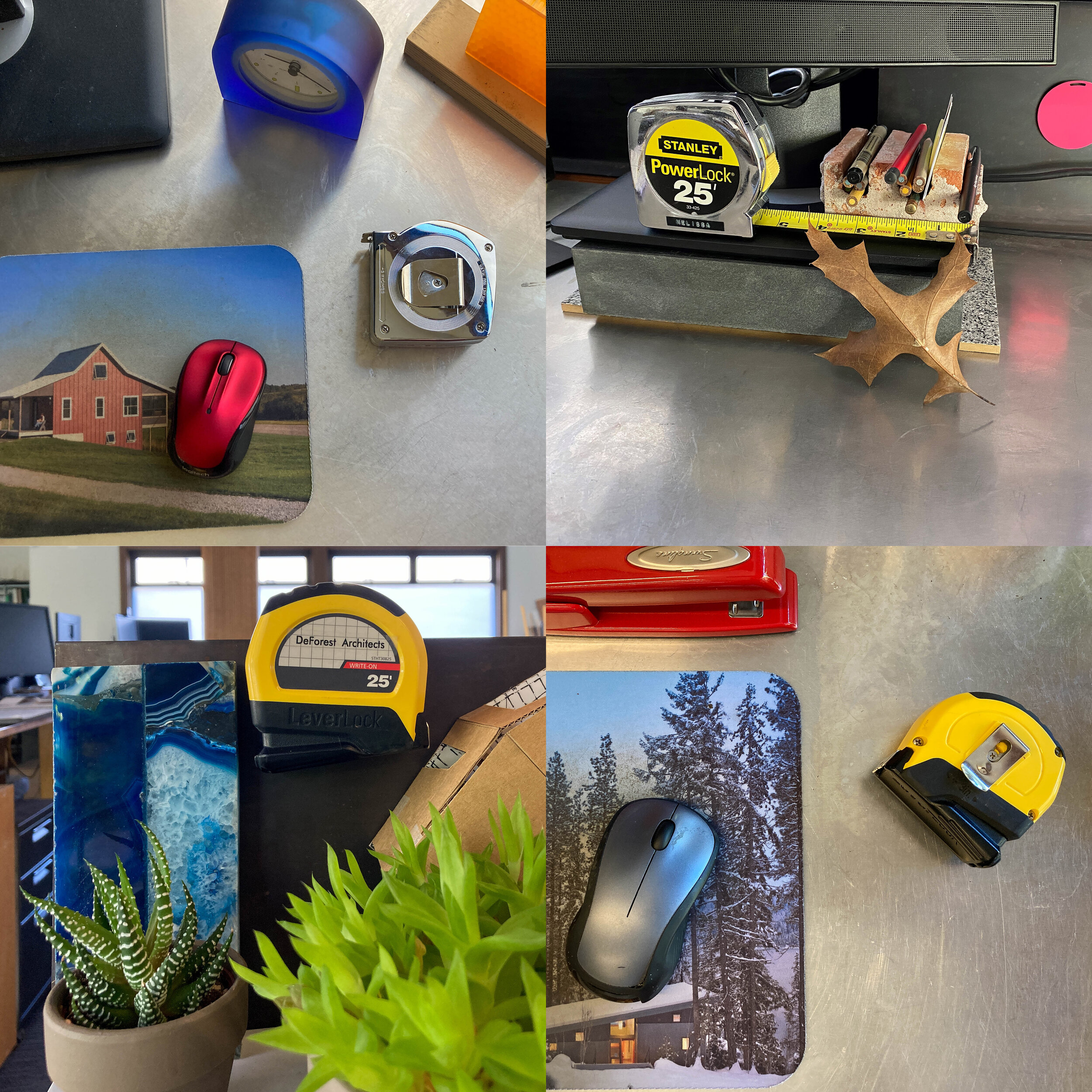

If there is one thing we know and understand, it’s how we experience spaces we use every day. With the help of an inexpensive tool, available at any hardware store, we can measure the rooms and objects around us. Engaging clients in the design process reminds us just how powerful a design tool this little metal coil can be.

Planning

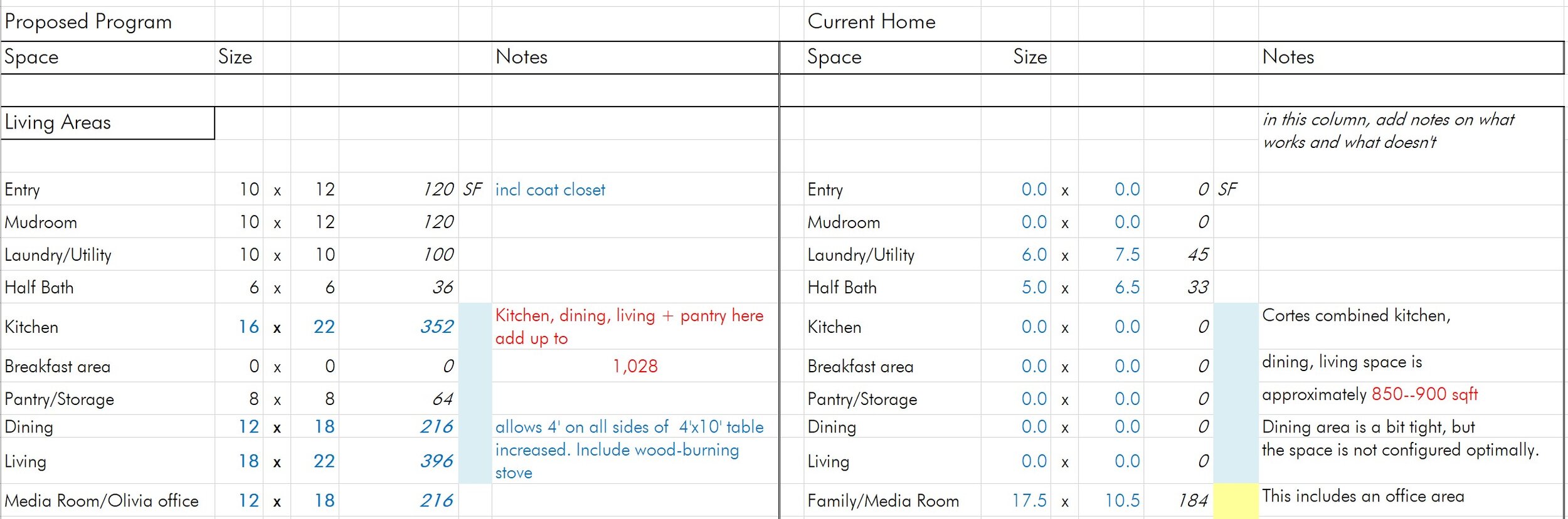

Before design even begins, we work closely with clients to create a “program”. This is simply architect lingo for ‘what rooms do you need and how big should they be?’ On one side of the spreadsheet we put the proposed list of rooms, sizes, and qualitative criteria. Next to that, we encourage clients to measure their current spaces for comparison. You might have an ideal office layout that you want to recreate, or a dining room that is too tight to fit all your chairs. Or it could be that you prefer your countertops to be a little higher than they are now, or you like the width of the hallways at your friend’s house. Whatever the feature is, getting into the habit of measuring things can help you tune into what feels best to you.

Right-sizing

When working with each other and clients in our office, we use the building - and trusty tape measure - to compare what is in the plans with similar sized areas. At times, we have used chairs, tape, boards, and string, to create a scale simulation of what is in the drawings. Whether it’s clearance around furniture or between cabinetry, or the length of a hallway, these real-world comparisons let us know when the dimensions feel right.

Full scale mockups

When questions come up about smaller scale details, like a railing or trim profile, we also turn to the low-tech tools we have on hand. Material samples, offcut pieces of steel, scraps of wood, or even office supplies. These informal full-scale mockups can be a great way to evaluate proportions of a detail in 3D. Often contractors build a mockup using the exact materials and details that will be in the final product, so we can compare variations, identify constructability issues, and give the client a preview of how things will look.

There will always be a wow factor with fully rendered computer models. Still, no matter how far technology gets us, the hands-on information we get from a tape measure means it will forever be a fundamental design tool.